Pick and Place Machines

Pick and Mix

It’s an endless task to keep up with the latest generation of components and its not easy for the older generation of pick and place machines to place these esoteric parts with accuracy. So we thought “why not buy a new state of the art machine?” and that’s exactly what we did. Having had experience of the Mydata TP9 (late 90′s technology) we have opted for the latest generation of the Mydata pick and place product line, the LX10.

There’s a lot of choice in the market, if the truth be known, too much! Once your start reading all the product literature for these machines you find that there’s a technology step and that all the products that can handle 0201 and even below are expensive and give or take all retail at similar price points for the machine. So the choice comes down to what these machines can do, how fast they can do it and what addon’s you need before they can actually do what they say they can do.

Feed Me!

It turns out that all the manufacturers start playing with numbers and you can bet your bottom dollar you need to carefully read the subscripts and superscript clues (i.e small print!) to figure out what specification a specific machine is – this is without exception!.

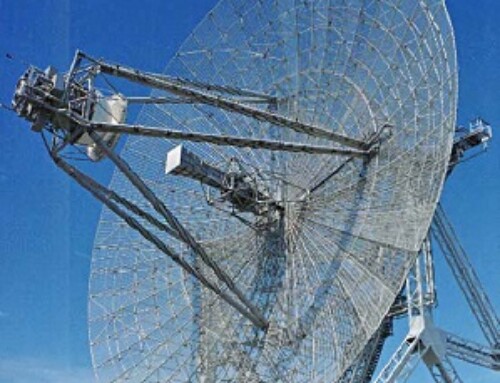

So after careful study we knew that we were particularly interested in ease of loading components and quick changeover from building one product type to another (we switch from different specifications of radar to led drivers to io boards to modems etc). This can be a painful process, I know this from first hand experience as changing parts on the magazines on our current machine can only be described as a painful and laborious task.

We knew that Mydata had a solution to this, their Agilis feeder system has to be one of the smartest feeder systems out there and is optimised for quick changeover of parts.

We also happen to be in the lucky position of having designed our own CAD software tool (BoardMaker3, which we sell worldwide) which means that with little effort we are able to extract data from our designs directly to our machine over the network. I can sit at my desk and transfer the file over the network and see the result on the Mydata machine web interface as components are mapped.

If you are not so lucky to have written your own CAD software then you will need a CAD/CAM front end and some manufacturers will supply this, Samsung for example, but not Mydata – you have to pay for this extra, thankfully we don’t need it because we produce data in the correct format from the source!

Bits and Bobs!

We went for the LX10 series machine with a high specification camera system (the machine will place down to 01005, that’s small!) so that we would not be caught out for smaller components requiring high accuracy placement, trust me it happens, not mentioning any specific tiny 6 pin BGA packages in particular….

We opted not to have things like electrical checking on R/C, Diodes and transistors based on the principal If you can’t read the label on the reel then you really shouldn’t be operating the machine, we’re engineers (in the true sense of the word) too so we really should know what we’re doing! We also went for the standard 16K speed rating, the 24K upgrade seemed a little extravagant, since its a software code we could always add that later – the camera system that the machine is installed with increases the placement speed anyway.

Can’t wait for the installation, only few long weeks left to wait!